SUV Lights.com

Photos and Videos

Philips D2R/D2S Factory Tour

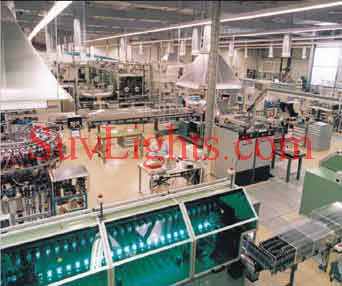

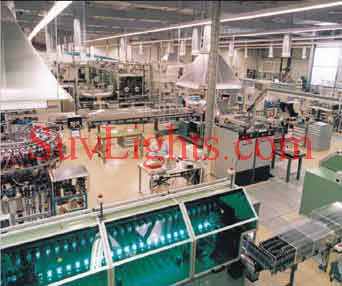

A new factory, built at Philips Lighting's chief competence

centre in Aachen, Germany is dedicated to the production of D2R/D2S bulbs.

The realization of the high speed production line demanded

a number of further breakthroughs in bulb production technology. These

included meeting stringent demands in the precision dosing of the gas filling,

as well as an alignment of the burner to the base to ensure optimum quality.

|

Special air conditioning and filtration installations

enable dust free conditions. This ensures that the stringent quality

levels needed can be achieved; particularly important at the crucial,

spectacular point in the production process where the electrodes are

inserted in the inner bulb and a carefully measured quantity of metal

salts and inert grasses are added. |

|

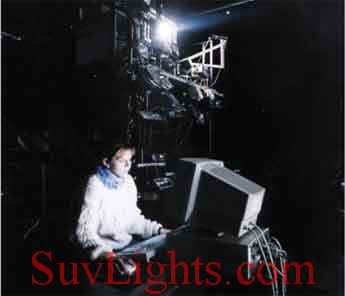

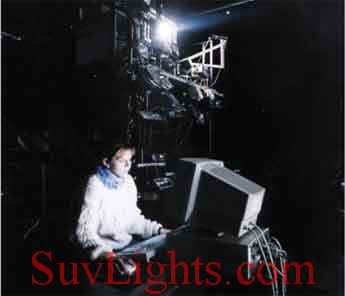

Headlight systems are evaluated at Philips dedicated

Automotive Application Laboratory at Aachen. |

|

Philips supports OEM set makers and automotive companies

by testing existing headlight systems and aiding the implementation of the

latest technologies. |

|

The high speed

D2R/D2S production line is fully computer

controlled. Utmost precision is ensured with the help of advanced

tools and machinery. Every single bulb is inspected for minimum

tolerances at various stages of the production process, using machine

vision and monitors. |

|

Each and every bulb produced,, is burned-in for one and a

half hours, with the electrical and lighting-technical parameters being

individually measured. |